CNC rope groove turning machine tool

The CNC rope groove device of the hoist is a specialized equipment designed and developed by Luoyang Weika Mining Machinery Equipment Co., Ltd. for the cutting of the lining of the mine hoist and the cutting of the crown wheel lining. This machine tool can effectively solve the problems of gnawing, shaking, low cutting accuracy, long cutting time, low efficiency, and high labor intensity when cutting rope grooves with old-fashioned cutting equipment, and is easy to operate, safe and efficient. After the first installation and debugging of this machine tool, there is a unified benchmark, which can easily achieve consistency in the depth of cutting rope grooves after cutting multiple rope grooves, ensuring that the bottom diameter of the rope grooves is the same. By comparing the cutting depth data of the rope groove before and after cutting, it is easy to determine the degree of wear of a certain rope groove, providing a reference for the adjustment and maintenance work of the steel wire rope for the mining party.

Key words:

CNC rope groove turning machine tool

Classification:

Product Details

Equipment Introduction

The CNC rope groove device of the hoist is a specialized equipment designed and developed by Luoyang Weika Mining Machinery Equipment Co., Ltd. for the cutting of the lining of the mine hoist and the cutting of the crown wheel lining. This machine tool can effectively solve the problems of gnawing, shaking, low cutting accuracy, long cutting time, low efficiency, and high labor intensity when cutting rope grooves with old-fashioned cutting equipment, and is easy to operate, safe and efficient. After the first installation and debugging of this machine tool, there is a unified benchmark, which can easily achieve consistency in the depth of cutting rope grooves after cutting multiple rope grooves, ensuring that the bottom diameter of the rope grooves is the same. By comparing the cutting depth data of the rope groove before and after cutting, it is easy to determine the degree of wear of a certain rope groove, providing a reference for the adjustment and maintenance work of the steel wire rope for the mining party.

This machine tool has a pure Chinese interface and is easy to operate, saving maintenance time for rope groove cutting work, improving production efficiency, and reducing labor intensity for workers. It is a sharp tool for maintaining the rope groove of mine hoists and has won multiple domestic patents.

Patent certificate

2、 Equipment features

1. Do not shake or bite the knife.

Avoid damage to the friction pad and wire rope, and extend the service life of the friction pad and wire rope.

2. Accurate feed control, high cutting accuracy and consistency.

The specific feed rate in each direction can be set according to the on-site working conditions, with a minimum setting value of 0.001mm. Each operation detail can be monitored and adjusted. Fully ensure that the diameter of all processed rope grooves is consistent, which can effectively adjust the tension of the steel wire rope and shorten the adjustment stroke of the rope adjustment cylinder.

3. High cutting efficiency, saving 80% of working time compared to traditional equipment.

During the normal production and maintenance time of each coal mine, the entire process of machine tool installation, alignment, debugging, cutting rope grooves, cleaning the site, and normal production can be completed. The cutting process is also not limited by the direction of rotation of the drum, and both forward and reverse rotation can be used for cutting work.

4. Simple operation, low labor intensity, and high safety factor.

CNC system, easy to operate. All movements of the machine tool are controlled through precise electrical programs, and each axial position can be set with a specific feed rate through an electronic display screen, without any manual operation and with a high safety factor.

5. High processing smoothness and roundness

The machine tool greatly improves the cutting speed of the cutting tool by selecting a high-speed electric spindle, and the surface smoothness and roundness of the processed rope groove are high.

6. Using the original installation foundation, the installation method is flexible and convenient.

The installation of the machine tool can use the original installation foundation base. After on-site technical personnel measure, align, and fix it, it can continue to be used.

7. High safety, with emergency stop function. During operation, the X-axis and Z-axis are interlocked to prevent misoperation.

8. It has the function of displaying the machining depth of the rope groove in real-time during turning processing.

9. Equipped with fully automatic processing function, the equipment operation modes mainly include handwheel mode, manual mode, and single step mode, and programming automation operation can also be adopted.

10. The minimum cutting amount for a single feed can reach 0.001mm, effectively ensuring that the accuracy error of rope groove turning does not exceed 0.001mm.

11. Identify the depth of rope groove wear online through servo coding and CNC system.

12. Equipped with extended ranging function for easy equipment upgrade.

13. Equipped with a laser calibration device for precise tool alignment.

14. Equipped with a horizontal calibration device for easy alignment of the working level during installation.

15. Adopting a customized CNC system, the system has dual analog output ports, supports importing processing programs from USB flash drives, and supports power-off memory function.

3、 Equipment model and technical parameters

1. Equipment model:

Well tower hoist JKM3.5 × 4:WK-SKC-J3.5 × four

Floor mounted elevator JKMD3.5 × 4:WK-SKC-D3.5 × four

2. Technical parameters:

Machine tool repeated positioning accuracy: 0.05mm

Control minimum movement: 0.001mm

Maximum movement speed: 1500mm/min

Maximum speed of spindle motor: 18000rpm

Spindle motor power: 4.5Kw

X. Z-axis moving motor power: 400w

Single feed cutting amount: 0.1-0.3mm

Linear speed of drum rotation: 0.1-0.5m/s

4、 Equipment execution standards

GB/T16462 Inspection Conditions for CNC Lathes and Turning Centers;

GB22997 Machine Tool Safety Small Specification CNC Lathes and Turning Centers;

GB/T23567.3 Reliability Evaluation of CNC Machine Tools - Part 3: CNC Lathes and Turning

Heart;

GB14048.1 Low voltage switchgear and control equipment;

JB/T10274 General technology Conditions for AC Servo Motors of CNC Machine Tools; JB/T10276 General technology Conditions for AC Servo Drive Units of CNC Machine Tools; JB/T11991 AC servo motors for industrial machinery digital control systems;

The electrical part of the equipment meets the relevant provisions of the Coal Mine Safety Regulations.

Installation site of tower lifting locomotive cutting device

Operation site of floor mounted lifting locomotive cutting device

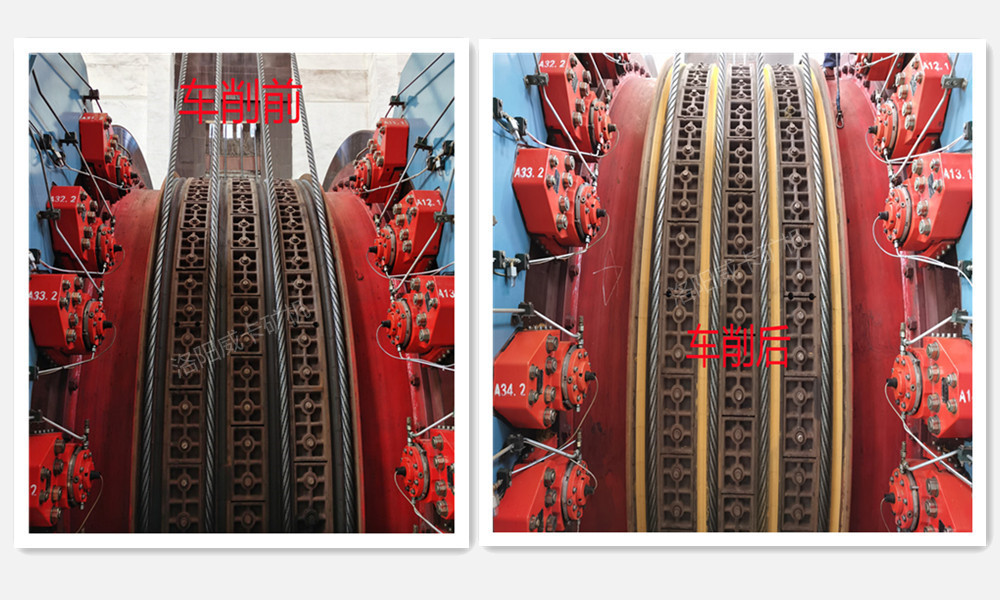

Comparison effect before and after turning

Related Content

We aim to win the market with high quality products and customers with good faith service

Online Message

Please feel free to leave us a message if you have any questions. We will contact you as soon as possible.